What can you do with a small engine repair course?

Oct 20, 2021 · Massachusetts Institute of Technology (MIT) Design and Manufacturing I may be beneficial to prospective small engine repair technicians who would like to understand how to create, build, and analyze mechanical designs. While those who take this free course may not want to invest in the materials to design the assigned robot, they can certainly benefit from the …

How do you disassemble a car engine?

Small Engine Repair Program Tuition. Take the first steps toward a new career with our online Small Engine Repair Program. Simply choose from one of our low-cost customized payment plans and get started today! Option 1: Pay in full. Save up …

What are some tips for taking apart an engine?

Small Engine Assembly – Notes Day 1 1. Remove head gasket residue gasket scraper • Use the gasket scraper to remove the head gasket residue from the block and head • Be sure not to dig into block while using the gasket scraper 2. Remove oil …

How to rebuild a small engine on a tractor?

Mar 20, 2015 · Dirt is your greatest enemy. Once the outside of the engine is cleaned, move it to clean work space and use your service manual to disassemble the engine. A good tip is use your video camera to tape yourself taking the engine apart. It’s great to be able to look at the tape to see what this thing is and where it came from. Taking the Engine Apart

How can I learn small engines?

9:2526:00Small Engine Repair and Maintenance Part 1 - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd then also you have the basics of an engine here which all engines have up top is a spark plug.MoreAnd then also you have the basics of an engine here which all engines have up top is a spark plug. Then just below you have the piston. And a connecting rod. And then you have an int an intake valve.

How do you disassemble a small engine?

7:2914:32Briggs & Stratton Small Engine Disassembly (#3319770010G1)YouTubeStart of suggested clipEnd of suggested clipIf necessary rotate the flywheel to loosen the rocker arms. Then use a 5/8 inch wrench to secure theMoreIf necessary rotate the flywheel to loosen the rocker arms. Then use a 5/8 inch wrench to secure the pivot nuts and a t20 Torx bit screwdriver to loosen the set screws securing the rocker arms.

Is small engine Repair difficult?

Unless you have the proper air/fuel ratio, a small engine will not start or run properly. Removing an air filter is usually relatively easy on a small engine, and if the engine starts and runs with the air filter removed, the repair may be as easy as simply replacing the air filter.

How do you take apart a lawnmower engine?

0:153:29Taking a Lawnmower Engine Apart - YouTubeYouTubeStart of suggested clipEnd of suggested clipI start by removing the screws here in the top cover. And then I removed three more underneath thatMoreI start by removing the screws here in the top cover. And then I removed three more underneath that that holds the gas tank on. And it just pivots back like so for.

What are the steps to disassemble an engine?

Remove switches and sensors.Remove the throttle linkage, cable, or wiring.Mark accessory brackets and remove accessories.Remove exhaust components.Remove and plug the fuel line.Determine whether to remove the transmission.Separate the engine and transmission/transaxle.Unbolt the engine mounts.

How do you disassemble a Briggs and Stratton engine?

Use a socket wrench to remove the spark plug. Remove the bolts holding the cylinder head in place. Slide the spark plug wire out of the way, and lift the cylinder head from the engine block, revealing the piston and valves. Turn the engine over and remove the bolts holding the crankcase cover in place.

What is the most common problem with small engines?

Carburetor. Most of the common problems with small engines point to fuels. However, if the carburetor fails to mix the fuel and air properly, engines malfunction. If a carburetor becomes dirty, it clogs easily which keeps it from functioning well.Feb 18, 2019

What tools do I need for small engine repair?

2:276:50BASIC Tools Needed for Small Engine and Lawn Mower Repair - YouTubeYouTubeStart of suggested clipEnd of suggested clipOkay a set of wrenches is a requirement you pretty much have to have a set of wrenches to do anyMoreOkay a set of wrenches is a requirement you pretty much have to have a set of wrenches to do any repair. And also nice to have a knife when Han a feeler gauge or one of them for spark. Plugs.

Why are small engines so hard to start?

What Causes Small Engines To Not Start? When engines do not start, spark plugs disconnected, dirty, or foul are commonly responsible for the issue. spark plugs should be replaced every season or two or four months. Likewise, you may want to ensure the spark plug gap is set correctly.Feb 20, 2022

How do you take a lawnmower 3.0 apart?

The ProcedureRemove the Old Module. Grip the trimmer firmly in one hand. ... Fit the New Module. There's a two-pronged piece on the back end of every blade module. ... Press Until it Snaps. Once the module is fitted, press at the module's front end (reversing the pull you used to free the other blade).Jan 27, 2020

How do you rebuild a lawnmower engine?

2:588:37Briggs and Stratton Mower Rebuild with Narration - Part 1 - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut if you just go around the circle. And remove each one all the way without slackening. Needs off.MoreBut if you just go around the circle. And remove each one all the way without slackening. Needs off. And that's a very bad thing to do because you can walk the head. So what you'll do go diagonally.

What can I do with a push mower motor?

7 Projects That Add New Life to Your Old Lawnmower EngineBuild a DIY Generator Using a Lawnmower Engine. ... Build a Wooden Go-Kart. ... Lawnmower Engine Powered Mulcher. ... Homemade Power Wheelbarrow. ... Convert it into an Outboard Boat Motor. ... Build a MINI-BEEP. ... Power Your MINI-DOZER MD196K Bulldozer.Oct 14, 2016

What types of small engines will I learn to repair in this course?

Penn Foster's online Small Engine Repair Program prepares students to repair typical two-stroke and four-stroke engines, outboard engines, and mari...

Why become a small engine mechanic?

Small engine mechanics play a vital role in servicing and repairing outdoor equipment such as lawn mowers and leaf-blowers. Mechanics who work on o...

How long does it take to become a small engine mechanic?

Depending on your education and experience, it can take up to a year to become a small engine mechanic. While postsecondary education isn't require...

What qualities make a good mechanic?

Good small engine mechanics are detail-oriented, have strong troubleshooting and mechanical skills, and are able to work in a variety of environmen...

The Course

The Crankin Engines course gives you a hands-on approach to learning about lawn mower engines by giving you the opportunity to take one apart and put it back together!

About Us

Rankin Barnes of High Point, NC, has 32 years experience teaching Automotive Technology at state and community colleges. He was the recipient of the Presidents Award for Teaching Innovation and the Excellence in Teaching Award.

What is Jacks Jack's small engine?

Jacks Jack's Small Engines has been providing parts for outdoor power equipment online since 1997. We also run a service center for outdoor power equipment like riding mowers, snow blowers, generators, chainsaws, and just about anything else.

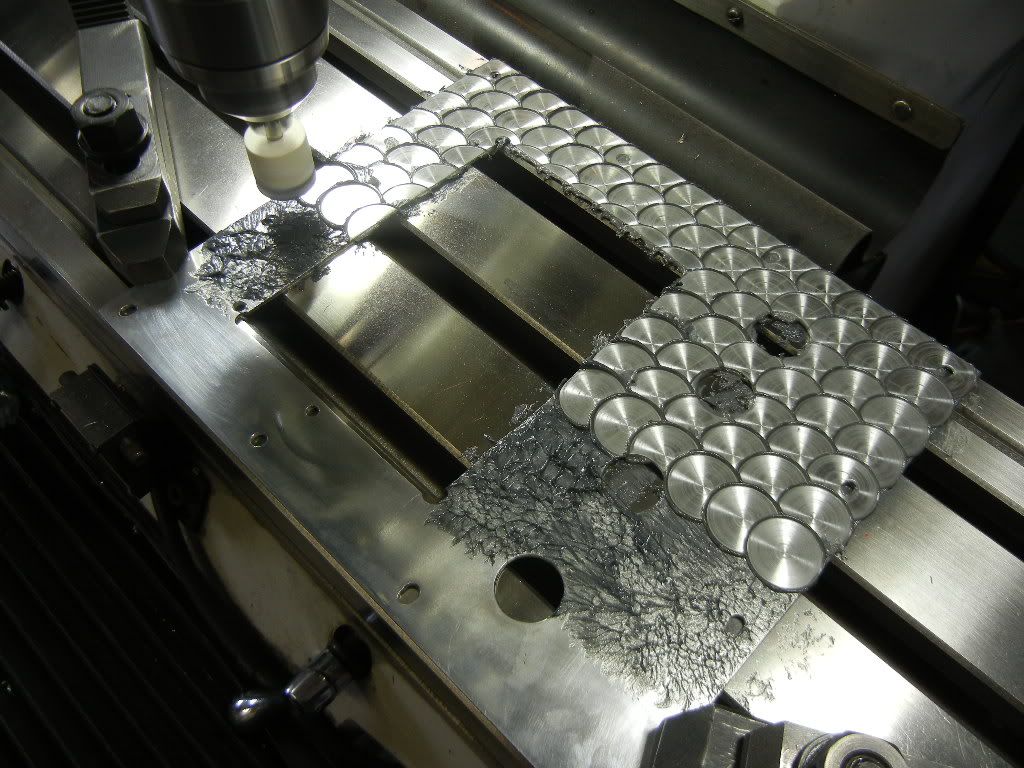

What to look for in a motor?

Important things to look for are signs of discoloration (caused by heat baking the oil into the part), aluminum that has melted and stuck to other components, scrapes and scaring. You want to know what has been happening inside the motor to be able to avoid another breakdown.

What are the quizzes in a class?

Quizzes are included for each class as well as alternate ways for students to demonstrate mastery. Students work as part of a team to rebuild their engine. Students can optionally build a work portfolio with writing, drawings, and videos.

Who is Rankin Barnes?

Rankin Barnes of High Point, NC, has 32 years experience teaching Automotive Technology at state and community colleges. He was the recipient of the Presidents Award for Teaching Innovation and the Excellence in Teaching Award.

Popular Posts:

- 1. what is amazon virtual assistant course

- 2. do you think taking a sociology course can help correct people's stereotypes why or why not

- 3. how to get to wilderness agility course

- 4. how to organize youtube playlist into course

- 5. wpi what are the consequences of failing a course

- 6. how does ekman respond to criticism of his work? course hero

- 7. what qualifies as a humanities course neumann

- 8. a course in miracles if you knew who walks besude you

- 9. halyna is a college sophomore who enjoys sun tanning course hero

- 10. which it course is in demand