How do you set up a CNC machine?

- How to use an edge finder.

- How to navigate through your machine’s control.

- Knowledge of basic CNC control commands.

How to operate a CNC lathe?

• Tighten the nut to lock the tailstock position for cnc wood lathe machine • Lock complete • Check the air pressure value, it should be 0.6 Mpa • Pull this lever first • Press this button to activate the air to hold the workpiece tightly • Clamping Complete Step 2. How to Set Stop Position and Offset Correctly

How to set a work offset on a CNC lathe?

The Difference Between The Tool Offset And Work Offset

- Work offset represents the position of the workpiece at which the All the axis lie at the zero position. ...

- For adjusting the master tool, the tool offset is the ideal one. ...

- When the conditions and the targets change, we have to change the work offset. ...

- Tool offsets depend on the change in geometrical shapes and sizes. ...

How to make a power drill lathe?

Homemade Wood Lathe

- History of Lathes. When I was making the lathe I was curious how it got its start and the history behind it, so I did some research.

- Parts. My lathe is similar to Matthias', but I decided to add some different parts to ease assembly and make it more reliable.

- Making the Base. ...

- Tool Rest and Tail Stock. ...

- Making the Head. ...

- Mounting the Motor. ...

How do you set up a CNC lathe machine?

0:005:40CNC lathe setup part 1 - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe power button it's a red dial on the left hand side of the machine. I'm now going to twist theMoreThe power button it's a red dial on the left hand side of the machine. I'm now going to twist the red V stop button we press start and this will boot the controller. The first step for your setup.

How can I learn CNC lathe programming?

G-Code ProgramsStart the CNC program.Load the required tool.Turn the spindle on.Turn the coolant on.Move to a position above a part.Start the machining process.Turn the coolant off.Turn the spindle off.More items...•

How do you set up a CNC machine?

Pre-Start. Before starting the machine, check to ensure oil and coolant levels are full. ... Start/Home. Turn power on the machine and control. ... Load Tools. ... Mount the Part in the Vise. ... Set Tool Length Offsets. ... Set Part Offset XY. ... Load CNC Program. ... Dry Run.More items...

Which course is best for CNC?

In summary, here are 10 of our most popular cnc coursesAutodesk CAD/CAM for Manufacturing: Autodesk.Introduction to CAD, CAM, and Practical CNC Machining: Autodesk.Multi-Axis CNC Toolpaths: Autodesk.Manufacturing Process with Autodesk Fusion 360: Autodesk.More items...

Can I teach myself CNC?

CamInstructor. This self-guided course is great for anyone interested in gaining CNC programming knowledge. It is also ideal if you are preparing for the IMs Certification Test. In this course, you will get introduced to CNC codes and will learn how to create CNC programs.

Can you teach yourself CNC?

Very basic CNC programming is easy to learn, provided that you understand basic math and have a grasp of how machining works. This can usually be learned within a few days. Intermediate programming skills can be learned within a year and advanced CNC programming can take several years to learn.

How does a CNC machine work step by step?

The CNC controller works together with a series of motors and drive components to move and control the machine axes, executing the programmed motions. On the industrial machines there is usually a sophisticated feedback system that constantly monitors and adjusts the cutter's speed and position.

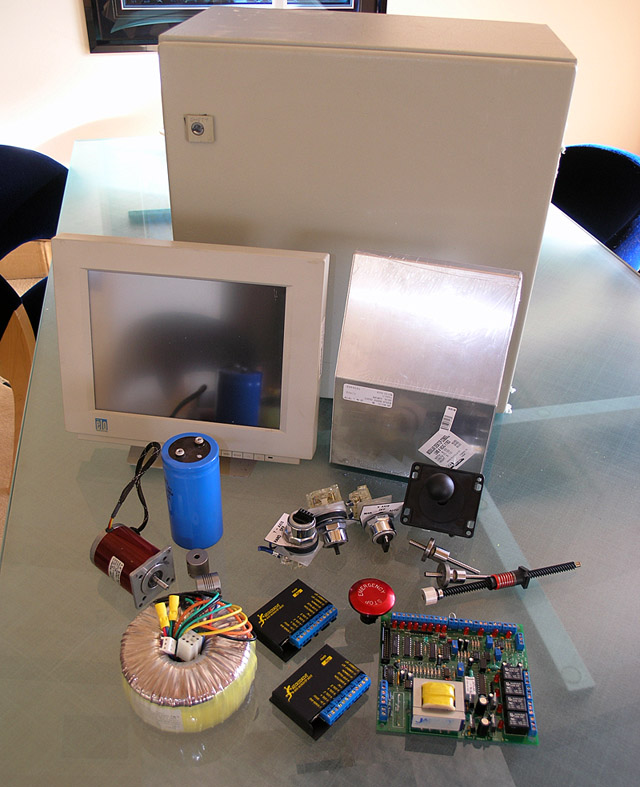

What do I need to build a CNC machine?

What you'll needElectrical parts, including: Processor/control board (some machines may use a PC) Stepper shield. Stepper drivers. Motors. Power supply.Mechanical parts, including: Tools, such as cutting tools. A frame. Bearings. Guides and supports. Spacers, washers, nuts, screws, and bolts.

What do you need to build your own CNC machine?

2:2410:43How To make a CNC machine for $500 - YouTubeYouTubeStart of suggested clipEnd of suggested clipNext I bolted more angle iron you're probably starting to see the theme here too the bearing plates.MoreNext I bolted more angle iron you're probably starting to see the theme here too the bearing plates. And used 1 inch by 1 inch steel tubing to attach the uprights to each other. Again.

Can I learn CNC online?

This online course will help you master what it takes to program, setup, and run a CNC machining center with a FANUC CNC. We begin with the basics - assuming you have no previous CNC experience.

Where can I study CNC?

CNC programmers do not need to have a degree, but some employers prefer candidates who've completed certificate, associate degree or apprenticeship programs in CNC machine operations, precision machining, machine technology or a related field. Voluntary certification is available.

How long does it take to learn CNC?

Typically it takes around four or five years of combined education and on-the-job training to become fully trained.

Now you have your new lathe

My preparation for my lathe started before I even received it. I had gotten the exact measurements for it, and cleared all the space I needed for it to have a home. I also did all of my pre-wiring. The Automate brand machines all require 3 phase power, so that meant that I was going to be getting a Rotary Phase Converter.

Now comes the unpacking portion

First of all, I took the time to open every cover, check all the wiring and the various connections to make sure nothing had come loose during shipping. This also involved opening up the electronics cabinet and checking everything over.

Steps after unpacking and leveling the machine

At this point, I was ready to hookup the power to the machine. After getting the instructions from American Rotary, and talking with the guys at Automate, it was just a process of connecting 4 wires into the machine, and turning it on.

Like what you read on CNCCookbook?

Join 100,000+ CNC'ers! Get our latest blog posts delivered straight to your email inbox once a week for free. Plus, we’ll give you access to some great CNC reference materials including:

Foundation

As per layout drawing make drill hole.Place the foundation bolt and apply concrete.Make sure that bolts have set hard in concrete.Place the machine leveling plates.

Machine Inspection

Check the machine for any damage.Clean the rust prevention coating by using kerosene.Lubricate the machine surface.

Machine Placement

Using machine anchoring rod lift the machine and move to foundation site.Lower it to suitable position.Place the machine on leveling plates.Assemble with foundation bolt and clamp it.

Leveling

Use leveling bridges or spirit level for leveling.Place the spirit level on machine.Check the level of both long and cross of machine.Loosen all the nut foundation bolt.Use the machine leveling bolt for leveling .This bolt may be with machine or leveling plates according to different machine.

Grouting

Check machine level and foundation bolt before grouting.Fill the gap between the machine base and ground with cement grout.leave for 24-30 hours.Recheck the level before operating.

How to Use a Lathe

There are several steps in understanding how to operate a lathe correctly. The computer-programmed aspect of the CNC lathe, as well as the complexities of this highly versatile machine, means that training and skill are required.

Tips for How to Use a Lathe Machine

While lathe operation may seem fairly straightforward, there are several tips you can keep in mind and mistakes to avoid in the process. These include:

How to set a lathe tool holder perpendicular to the part?

1. Turn off the lathe machine, prepare a simple metallic ruler. 2. Mount a cutting tool onto the tool holder or tool post securely and set the holder perpendicular to the part. 3.

What is turning a tool?

Turning is a metal cutting process uses a single-point tool to produce cylindrical surfaces oriented primarily parallel to the workpiece axis, while the tool is fed into the part radially, axially or both ways simultaneously.

Popular Posts:

- 1. why do college have conspiracy course

- 2. fscj how to enroll in a course not listed on your requirements

- 3. why was major course of study chosen?

- 4. how much to charge for a pilot course

- 5. how to get ltc course in houston

- 6. how to create a continuing education course for nurses

- 7. what is the best golf course app

- 8. what does the army call basic noncommissioned officer course

- 9. what is an ins course

- 10. when refinancing your mortgage, you should consider: course hero