What are coarse thread screws used for?

They fasten to these surfaces better than other wood surfaces. There are many other wood types as well where these coarse thread screws are used as well which include woods such as Pine, Cedar, Spruce, Fir, Aspen, Poplar, Basswood, Plywood, Butternut, MDF, Particle Board, Melamine, etc.

What are fine threaded screws?

With all that we have seen in defining and describing the fine threaded screws, these fine threaded screws are stronger in terms of their tensile strength and their claiming capability as they are harder to shake and vibrate.

What is the difference between fine thread and course thread bolts?

As an industry standard, the plating needed for course thread bolts is 20% higher than the one required by fine threads. In addition, due to their distinct manufacturing processes, the plating on fine threads tends to have more gagging and presents more assembly problems compared to coarse threads.

What is the difference between machine screws and threaded screws?

A machine screw (on the right) doesn’t have a pointed tip. The treads of a screw wrap around the shank. Together, this is the part that drives into the material. The threaded part of some screws stops before it gets to the head, while other screws are fully threaded.

Why is a coarse threaded screw good?

Coarse thread fasteners are an excellent choice for most applications. Commonly chosen for construction simply because their threading can be lightly damaged and still work effectively. Coarse threading allows for more material to sit between these threads as they are installed.

What holds better coarse or fine thread?

Size for size, a fine thread is stronger than a coarse thread. This is both in tension (because of the larger stress area) and shear (because of their larger minor diameter). Because of the smaller pitch, they allow finer adjustments in applications that need such a feature.

What are the advantages of coarse threads?

Pros of Coarse Threads: Greater resistance to stripping and cross-threading. Faster installation than fine threaded fasteners, partially because they aren't prone to seizing during tightening. This can result in significant time and money savings in high volume assembly applications.

What is the difference between coarse and fine thread screws?

What is the difference between fine and coarse thread fasteners? A. A fastener with a fine thread equates to a fastener with a large number of threads per distance along the fastener. In contrast, a coarse thread fastener equates to a fastener with a low number of threads per distance along the fastener.

What are two advantages to coarse threads over fine threads?

Coarse threads are more durable and have greater resistance to stripping and cross-threading. The height of each thread is greater than the corresponding fine thread so there is more material between each thread making flank engagement greater.

Can I use coarse thread screws in hardwood?

When it comes to fine thread screws, hardwoods are more preferable. These hardwood surfaces are too hard and dense and hence coarse thread screws may not be the best fit for all such hardwood surfaces.

Should I use coarse or fine drywall screws?

Fine-thread drywall screws are best for installing drywall to metal studs. Coarse threads have a tendency to chew through the metal, never gaining proper traction. Fine threads work well with metal because they are self-threading.

Which thread is used for general purpose fastening?

Unified National Coarse threads, UNC threads, are the most common general fastener thread.

What are the cons and pros of selecting a coarse vs fine thread for a fastener?

Fine threads also possess larger minor diameters, which provide high shear strengths. Coarse threads tap better into brittle materials and are less likely to cross thread. Coarse threading lends itself to thicker coatings and platings before thread adjustments need to be made.

How do you know if its coarse or fine thread?

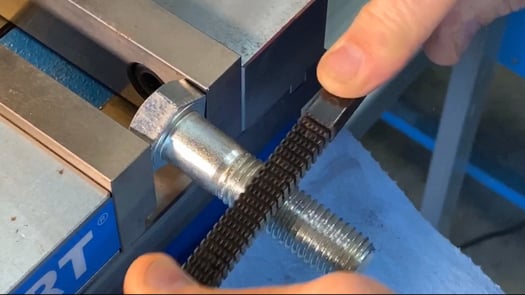

To be classified as coarse, the threading must be deep set and wide. On the other hand, fine threaded fasteners will have narrower, shallow ridges and a smaller pitch, with a higher number of threads per axial distance than coarse threaded bolts.

Can I use fine thread drywall screws on wood?

Fine thread drywall screws are made specifically for use with steel studs. Fine thread screws can be used when installing drywall on wood studs, but coarse thread drywall screws cannot be used with steel stud framing. Coarse thread screws are better suited for wood stud framing.

What screws to use on drywall?

Most drywall projects require coarse-thread drywall screws. The coarser threads provide superior grip to the wood which thereby increases holding strength. Coarse-thread screws are best for use in wood studs or joists. Fine-thread drywall screws are the other option.

Why use coarse thread fasteners?

Commonly chosen for construction simply because their threading can be lightly damaged and still work effectively. Coarse threading allows for more material to sit between these threads as they are installed.

What is fine threading?

Fine threading consists of very shallow peaks and valleys when compared to coarse. As a result, tapping a hole for fine threading can be significantly easier as there is much less material to cut to form the threads. Fine threading also has a very shallow pitch (helical angle).

What is a helical thread?

This helical shaped threading can be either wide set and deep which are considered coarse thread while a more narrow helical shape with shallow ridges is considered to be fine thread.

What is fine thread fastener?

Fine thread fasteners are ideal for environments where vibration is considered an issue. Now that you know how to compare coarse thread vs. fine thread fasteners, you can make the right choice when deciding on which fasteners you need for a project.

Which is better, coarse or fine thread?

Fine Thread. While coarse threading fasteners are better suited for general purpose applications, fine thread applications tend to have many benefits that make them the ideal choice when specifics matter. Fine threading has a higher tensile strength than coarse threading and it can be measured more accurately.

Is it harder to strip or cross thread?

Due to this, it is harder for coarse threaded fasteners to strip or cross thread. Their extra tolerance allows for nicks or marring to occur on the edges of the threading without inhibiting the ability to fasten them. Coarse threading is also much less likely to gall then fine threading.

Does coarse threading gall?

Coarse threading is also much less likely to gall then fine threading. Fine threading requires many more turns per inch which generates more friction. Excess friction dramatically increases the chance of galling in fasteners. Regardless we recommend using an anti-seize solution especially on stainless steel fasteners.

Why do people use drywall screws?

The use of drywall screws in home construction quickly became popular because the screws have better traction and go into studs faster. Advertisement.

Why is the tip of a fine thread drywall screw sharper than the tip of a coarse thread screw?

The tip on a fine thread drywall screw is sharper than the tip on a coarse thread screw. This is so that is will more easily pierce metal. As a result it takes less physical pressure to start a fine thread screw. Advertisement.

What is fine thread drywall?

Fine thread screws are intended for use in commercial construction or in a structure with metal beams. Coarse thread drywall screws are intended for residential construction or in a structure with a wooden frame.

Do coarse thread screws pull out faster?

As a result they have a slightly higher pull-out resistance than fine thread drywall screws. Coarse thread screws, as a result of their lower thread count, also screw in faster. Advertisement.

What is the role of threads in fasteners?

When it comes to fasteners, threads are key. Threads determine how well fastener components (like nuts, bolts and screws) hold materials and machines together, and maintain their integrity over time.

Why are fine threads preferred?

When working with stainless steel, aluminum, titanium and other alloys, fine threads are preferable, particularly because of their strength.

What is coarse thread?

Coarse threads are typically called for in most industrial applications, particularly in aviation and military situations, due to a variety of advantages.

What is the number to contact Global Certified Fasteners?

Still unsure what type of thread is right for your project? Contact the fastener experts at Global Certified Fasteners at (708) 450-9301 or [email protected] and we’ll be happy to help you find what best meets your application’s requirements.

Can fine threaded bolts gall?

Fine threaded bolts can also gall (when metallic surfaces slide against one another and friction and adhesion cause material to be pulled from one surface and then adhered to the other) more easily than coarse threads, and they are often harder to obtain.

Why are coarse threads better than fine threads?

The short answer is that for general industrial applications, coarse thread bolts present several advantages over fine threads. Higher resistance to stripping. In applications where the length of the thread engagement is short, coarse threads are preferable due to their higher resistance to stripping. Innately, coarse threads have ...

Which is stronger, coarse or fine thread?

It's a legitimate question, considering that coarse threads are stronger and have an overall greater resistance to cross-threading and stripping, while the fine thread fasteners have a slightly larger tensile stress area. The short answer is that for general industrial applications, coarse thread bolts present several advantages over fine threads.

How fast is a 3/8-16 thread fastener?

They are easier and faster to assemble. A typical coarse thread fastener of 3/8-16 inch can be installed almost 70% faster than its 3/8-24 fine thread counterpart, thus saving you time, money and energy.

Why do stainless steel nut threads gall?

Galling occurs due to abnormal surface friction and the closer the fit between the mating threads, the more welded the nut will be.

What does extra height mean on a bolt?

The extra height is typically around 33% for coarse threads, meaning there' s considerably more material to resist stripping. Because the gaps obtained in a fine thread bolt are shallower, it means that they are more likely to be distorted by a nick of a certain dimension.

What is the purpose of screws?

Screws are also used to hold things together where expansion and contraction of the wood can be an issue. A common use is to attach a tabletop to a base. The screws will be set into a slot, allowing the wood to move as humidity changes. Using screws to attach a table top.

What is a machine screw?

Machine Screws. Machine screws have no points and are intended to use in holes that are already tapped or with a nut. They are threaded along the entire shaft are sold in threads per inch. When you buy them, make sure the nuts’ threads match.

What screws are used to join two pieces of wood together?

Wood screws are widely available in all home centers and hardware stores and are designed to join two pieces of wood together. They are threaded part of the way and then have a smooth shank at the top. This helps hold the screws in place. They are relatively inexpensive and come an all kinds of diameters and head shapes. You will usually want to use the ones with the tapered heads. Unfortunately, in the U.S., most woodscrews are still only available with Phillips heads instead of star or square drives.

What is a slotted screw?

Slotted screws are the original method for driving a screw. Like the name implies, it’s just a slot that a flathead screwdriver turns. For this reason, these types of screws are commonly called flathead screws way more often than slotted screws.

How many tpi is a screw?

Common wood screw diameters. In the U.S. threads are sometimes indicated in threads per inch, usually 24 or 32 t pi. These are important to know with machine screws or bolts where you need to get a nut to match. Sometimes wood screws come in coarse or fine threads.

What is star drive screw?

Star drive screws are becoming more and more common in the U.S. and are my absolute favorite type of drive. The star shape virtually eliminates cam-out and the driver almost never slips out. Plus they can accommodate a lot of torque. Usually they are sold on premium quality screws that won’t snap if tightened too much. And when you buy a box, it usually comes with the driver tip you need.

Can you use stainless steel screws on a boat?

For even better corrosion resistance , especially on boats and in salty marine environments, you can use stainless steel screws. While they offer the best protection from the weather, they are not as strong as deck screws and are very expensive.

Why are fine threads used?

Because of the smaller pitch, they allow finer adjustments in applications that need such a feature. Fine threads can be more easily tapped into hard materials and thin-walled tubes. Fine threads require less torque to develop equivalent bolt preloads.

What is the difference between coarse and fine threaded bolts?

What is the difference between fine and coarse threaded bolts? Bolts with coarse threads have a larger pitch (fewer threads per axial distance) compared to fine threads. A coarse threaded bolt is specified for most applications unless there is an overriding reason to use a fine threaded bolt (e.g.

Is fine thread stronger than coarse thread?

The potential benefits of fine threads are: Size for size, a fine thread is stronger than a coarse thread. This is both in tension (because of the larger stress area) and shear (because of their larger minor diameter). Because of the smaller pitch, they allow finer adjustments in applications that need such a feature.

Need Help?

For Technical Support, please call 800-447-8638 or send a message. Reps are available Monday through Friday from 8am to 5pm CST.

Recent Workbench Survey Legitimacy

Yesterday, I received an email wanting my opinion on Kreg adding high end workbenches to their product line and wanted to know before I clicked the link if this is a legitimate survey or some phishing scam. Here's the link I was provided (… Continue

Pantry slides for heavy application

Recently purchased two 96" tall pantry cabinets that are 23" deep that only came with two adjustable shelves and two fixed, (one at about 55" and one at the very bottom). Shelf holes in the walls are drilled 2" O.C. Like most store-bought… Continue

Popular Posts:

- 1. why are you taking this policy course?

- 2. what are the green tees on a golf course for

- 3. how much do you make working at a golf course

- 4. how long do you have to file chl course paperwork?

- 5. if not a holder in due course what are they?

- 6. how do you update course on a garmin approach s2

- 7. how is course hero

- 8. what if you miss course request for va te h

- 9. how many course credits are required to graduate high school?

- 10. which is not a constitutional influence we have studied in this course